正文

3D printers will shape the factory of the future

MANUFACTURING advances often take time to catch on. Only later does their real significance become apparent. The flying shuttle, invented in 1733 by John Kay, a British weaver, allowed the production of wider pieces of cloth. Because its movement could be mechanised, the shuttle later became one of the innovations which paved the way for the Industrial Revolution. In 1913 Henry Ford brought motoring to the masses by making his Model T on a moving assembly line; but it was Ransom Olds, a decade earlier, who had come up with the idea of an assembly line to boost production of the Olds Curved Dash. Throughout the 1980s factory bosses scratched their heads over Taiichi Ohno’s Toyota Production System and its curious methods, such as the just-in-time delivery of parts. Now it is the global benchmark for factory efficiency.

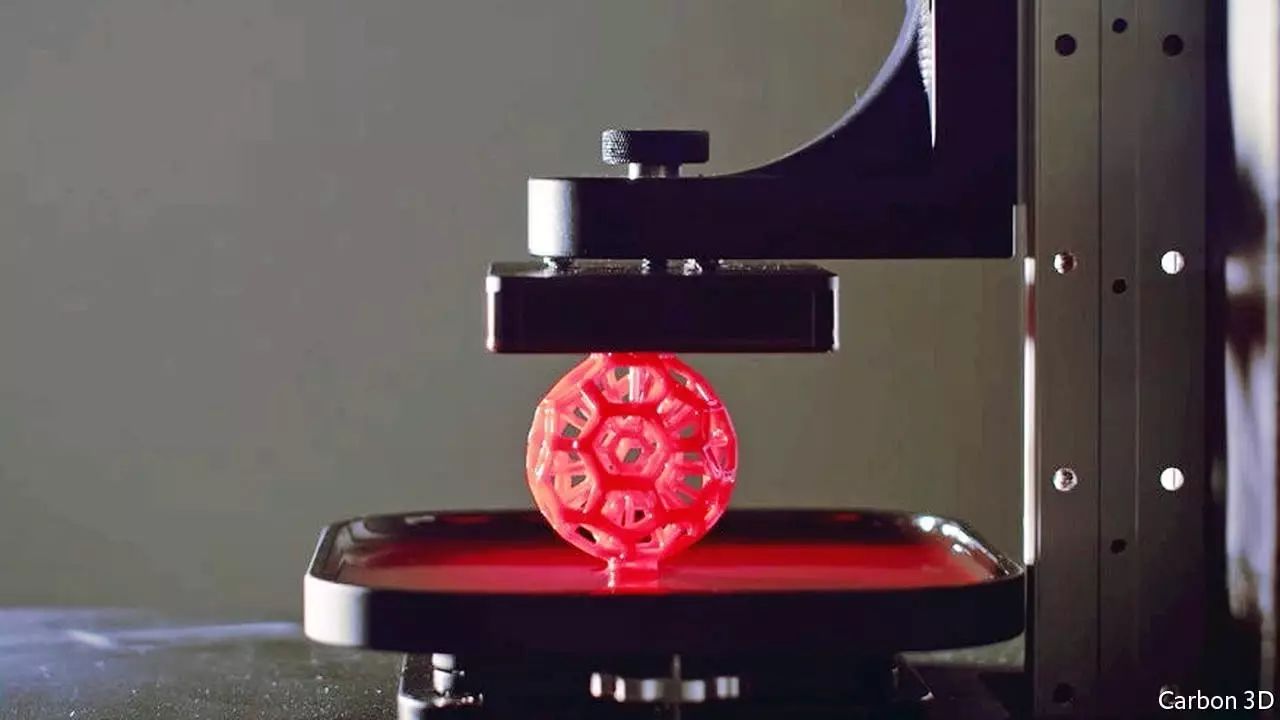

What, then, to make of the potential of Chuck Hull’s invention in 1983 of “stereolithography”? Mr Hull is the co-founder of 3D Systems, one of a growing number of firms that produce what have become known as 3D printers. These machines allow a product to be designed on a computer screen and then “printed” as a solid object by building up successive layers of material. Stereolithography is among dozens of approaches to 3D printing (also known as additive manufacturing).